(no subject)

The internal view of polygonal masonry in Peru

The ancient technology of casting stone blocks in South America

Different manufacturing techniques of polygonal masonry blocks

Concrete polygonal masonry technology in Peru. New evidence

Sources:

#^https://rblogger.ru/2014/06/16/ollantaytambo

#america #antiquity #art #artefacts #casting #history #hoax #marble #masonry #past #peru #revision

My articles about the differences in methods of manufacturing blocks of polygonal masonry, as well as about the version with a description of the casting technology (or rather, the molding of such masonry) made of geo-concrete - caused a heated discussion:

The ancient technology of casting stone blocks in South America

Different manufacturing techniques of polygonal masonry blocks

Concrete polygonal masonry technology in Peru. New evidence

There were many comments, the authors of which, in spite of the facts and explanations given in the articles, argued that the blocks was rubbed to each other.

The best way to verify this is to repeat such a laying with just such a technique with obtaining exactly this quality of block mating. But no one ever made an attempt to repeat it. Well, of course, builders have spent dozens of years for grinding in, and modern man has so much time. But that's why skeptics believe that the ancients did not value time? And that the ghostly result over many years would not be expected by any customer, as now.

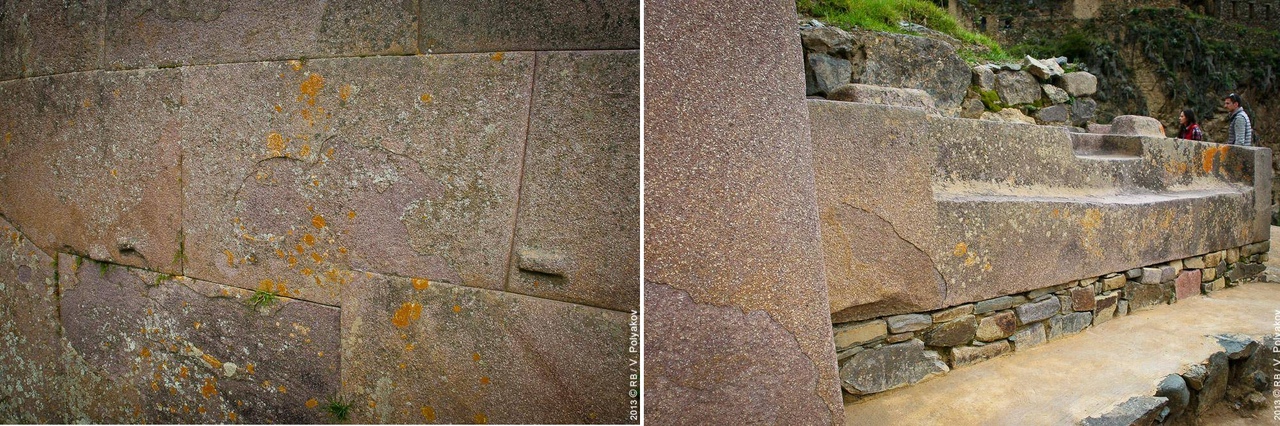

The surviving segment of polygonal masonry. The rest is a rubble stone on the solution. We see that there are rims on the side faces (which were internal). Could it have survived the process of grinding stones? Scarcely.

In this article, I propose to examine photos that show the inner edges of the destroyed sections of polygonal masonry in Peru. Photos posted by Evgeny Berzin in the Travel group and artifacts. Peru, Bolivia, Mexico, Middle East on facebook.

The rim on the edges close-up

My opinion is that if this was achieved by grinding, then such a rim could not remain. And it was formed due to the fact that the higher unit pressed into the lower one, since All masonry was molded from plastic material, geo-concrete.

I marked these places with a visible border.

The blocks themselves, while gaining strength, were still expanding, turned out like kegs, and when expanding, pressed each other with adjacent faces. Even if a small volume remained unfilled by rock, it was filled during expansion. That is why we see such a picture of the fantastic contact of blocks of polygonal masonry.

When moving the stone back and forth in the process of grinding, it would repeat the contour of the underlying block and this border, even if it was originally worn out. But there are no signs of this.

I propose to think: in general, is it really possible to grind the stone to the neighboring ones in several planes? Even with a superficial reflection on the process, it becomes clear that the lower edge under the weight of the stone will wear out faster than the side. And if the side face is oblique or curvilinear, then pairing along them with simultaneous contact with all faces will not work. Face abrasion should be uniform.

The fact that this block is a casting with a subsequent increase in the volume of the stone, this photo shows:

Recall photos of growing stones. There, too, is the same peeling of the rock as the shell. The following happened in this block: the surface layer hardened very quickly (reaction from the CO2 of the air), and the internal masses, increasing, broke this “shell”.

Bloated blocks. This form of processing and grinding stones can not be explained.

The following photos are from this location:

How can attrition such internal faces of blocks? This is exactly the depression in the plastic mass.

Another open block with earlier inner edges. Also inward bulging in its mass.

This photograph shows that the upper unit stood immediately on the lower two and left a mark on them. No grinding in such a trace can not be explained.

The Sacred Valley of the Incas. And this inner corner in the stone on the left how to grind?

On these blocks, the “shell” also gradually fell off in the process of expanding the block.

I think that these examples clearly show that the lapping of blocks in a polygonal masonry of such a level is impossible. This can only be built by molding concrete. What is geobeton and where it came from (questions from new readers) - I wrote in previous articles.

Sources:

#^https://rblogger.ru/2014/06/16/ollantaytambo

#america #antiquity #art #artefacts #casting #history #hoax #marble #masonry #past #peru #revision